Our technology

Flexible, high-end solutions due to the five-axis machine concept

The recipe for success of our tube lasers is the unbelievable manoeuvrability of the laser cutting head, which is perfectly attuned to the challenging demands of machining metal profiles. Of course there are adapter solutions and upgrade modules which can also be used to machine tubes in a conventional flatbed laser, however they are heavily limited in terms of their possibilities and a rather expensive way of achieving a 'simple' solution with existing methods. The dimensions as well as the precision and productivity which can be attained using such hybrid machines are extremely limited, unfavourable even.

- Axis / X-axis / Tube feed motion

The first axis is realised by the feed motion of the material in the clamping chuck. The chuck can move on the feed device with breathtaking speed, and precision in the order of tenths of millimetres. - Axis / A-axis / Rotation

The rotation of the tube in the clamping chuck is the second axis. The tube can be rotated 360° about its own axis. - Axis / Y-axis / Lateral movement

The third axis is located on the laser cutting head and moves it back and forth with a lateral movement. - Axis / Z-axis / Height control

The fourth axis is the height control of the tube laser cutting head. Ultra-sensitive sensors detect the geometric shapes and adjust the height of the cutting head together with the cutting speed to the tube feed rate. - Axis / 45° / Diagonal cut function The manufacturers have created an additional, fifth axis with the tube laser cutting head, which is able to pivot by up to 45°. Thus it is even possible to achieve the complex diagonal cuts which have been almost impossible in high-quality metal profiles to date.

Diagonal cutting – one function that changes everything

Our machines' ability to pivot their cutting head in an additional, fifth axis, even up to 45°, represents the solution to one of the greatest problems in modern profile machining. When the laser beam always meets the tube being machined at precisely 90°, this results in an elliptical cutting edge (see Figure 3). Now the option to pivot the tube laser cutting head, together with the feed axis, makes it possible to achieve a fully diagonal cut.

Figure 1

As versatile as our inventory of materials

The versatility of the tube laser cutting systems can be easily demonstrated based on the variety of metal profiles they are able to machine. Where until recently only standard round and square tubes could be cut, now every contour imaginable made from all common and special profiles can be cut.

Open profiles continue to pose a particular challenge for our programmers, which we can use to develop our skills and expand our range of services. In terms of material properties, our tube laser systems are able to cut materials from S235 and S355 to fine-grained structural steel, including all non-rusting stainless steels and variants of aluminium.

Innovative connections and positioning aids

Here you can find some examples of the multitude of possible applications of tube laser technology. The distinct machining shape of tube laser cutting and the associated reproducibility offer numerous solutions for complex connection types. Consistent use and the ability the take account of these possibilities right from the planning phase significantly reduce or simplify subsequent production and assembly steps.

The selection shown here represents only a limited overview of the options available. We would be happy to plan entirely new and individualised approaches together with you to manufacture a product that is even more innovative, efficient, and high quality.

Push-fit connections

For push-fit connections, little pins are left behind during the normal tube laser cutting process which fit perfectly into the recesses in the matching part. The extreme precision of tube laser technology allows precise positioning aids to be holed out in the material even while cutting is in progress. They then make subsequent assembly substantially easier, as measuring and alignment are made unnecessary thanks to the precise positioning.

Articulated frame

With the targeted cutting and placement of longitudinal girders, in just a few simple steps we are able to construct a frame or a corner connection from one metal profile, which consists of a single continuous element and also offers a much more stable foundation than conventional structures. This saves both time and material!

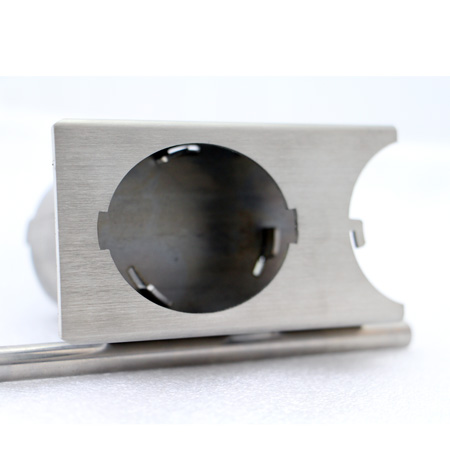

Bayonet connections

Bayonet connections have characteristic hook extensions, which are inserted into the opening on the matching part and are then twisted by turning or pushing into the connecting piece. This technology even removes the need for additional welding work under certain circumstances.

Mitres

Whether on a curve or an edge, a mitre reliably connects two workpieces and prevents the component from slipping out of place again. Especially for frame constructions made from square profiles, this type of connection saves the construction engineer a lot of work and risk.

Send Your file as DXF, DWG, STP, or PDF

(multiple files packed as ZIP)

©Trumpf-Group